|

Mr. Nakajima, who was playing an active role in the development

of domestic technologies, started building the Grand masters of aircraft body engineering at that time were said to be rivals, "Tukagoshi for the Zero fighter at Mitsubishi", and "Tei Koyama at Nakajima". The engine at Nakajima was master minded by "Ichiro Sakuma of Nakajima Engine". Sakuma had studied internal combustion engine design on his own while working at the Yokosuka Naval Arsenal, and was selected as the first young engineer to be recruited by Mr. Nakajima when establishing the Airplane Institute after his retirement. In the beginning, partially due to the Navy's instruction, Nakajima produced a water cooled V-type 400PS engine that was licensed by Loren, France. Then, 127 units of the same W-type 450PS engine were produced until 1929. Loren Dietrich was an automobile manufacturer with a great history and entered airplane engine production in 1915, one year after World War I started. They started with a straight six, water cooled 100PS engine, then produced the Type 15, 275PS engine that was installed in a 2-seater Spud airplane. The engine got high reviews because of its excellent reliability. The Loren engine, made by Nakajima, was installed in the Nakajima Breguet 19A-2B reconnoiter carrier planes and the Type14-3 reconnoiter carrier planes, but the appearance of the engine with its exposed valves was not as attractive as the Hispano-Suiza. Not very long after Loren production started, Nakajima eyed

the newest product from Gloster in England - the Gamecock fighter

plane, and judged that its radial engine was becoming main stream.

He then acquired a manufacturing license of the air-cooled 9-cylinder

radial engine, Jupiter, from Bristol in England in 1925. Air

cooled engines at that time were using radial cylinders rotating

together with the propeller, but Nakajima overheard that an engine

with good cooling capability with fixed cylinders was being developed

in England. The Jupiter engine was ahead of its time and already

utilized the most advanced technologies such as an automatic

adjustment device for tappet clearance, spiral piping for even

intake distribution, and a four-valve intake and exhaust system.

In 1927, after inviting two production engineer instructors from

the Bristol company, Jupiter Type 6 420PS and Type 7 450PS with

a turbo charger were put into production. 150 units of the Type

6 engine were installed in Type 3 fighter planes and Nakajima

Fokker transport planes. In addition, about 350 units of the

Type 7 engine were installed in Type 91 Army fighter planes.

The Loren engine design instructor, Moreau from France, lived in a Japanese rooming house and delivered a series of lectures in other companies and schools. He adopted himself to Japanese culture, but the other instructor, Burgoyne from Bristol in England, continued to live like a British gentleman. Burgoyne hated the smell of Takuan (Japanese yellow pickled radish). He stayed at the Imperial Hotel, and it is said that he got off the train at Ogikubo, one station before Nishiogikubo (the closest station to the company) because there was a pickle shop in front of it.

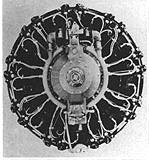

Nakajima Jupiter Type 6 Using this engine, the product nationalization plan was carried

out gradually. By studying an air cooled 9-cylinder radial engine

(the American Wasp), the first originally designed air cooled

9 cylinder, (the 450PS "Kotobuki" engine) was completed

in 1930. Jupiter was made based on artisanry engineering, and

the productivity was not good. As an example, the cooling fins

were formed by machining. Nakajima then tried to combine good

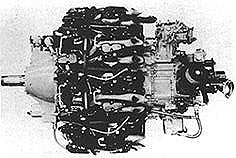

points found in Jupiter Nakajima engines were widely used not only in warplanes but in civilian planes as well. About 7,000 units for civilian use were produced up until the end of the war. In the Army they named aircraft engines by type codes such

as Ha-25 or Ha-112, while in the Navy, they used nicknames such

as "Homare (honor)" or "Kasei (Mars)". At

Nakajima, as mentioned before, a single Kanji, (Japanese character)

carrying good luck such as "Kotobuki(auspicious)",

"Sakae (glory)", "Mamori (guard)", or "Homare"

was used. Mitsubisi used star names such as "Kinsei (Jupiter)",

Hitachi used wind names such as "Ten-pu (wind in the high

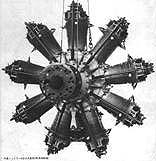

sky)" At the same time, an engine was developed upon the Navy's request called "Sakae", of which the Army name was Ha-25 (crick here for details). This engine was uniquely engineered as an engine of small size, light weight, and high performance in small displacement and fewer cylinders. This was then installed in Type 97 carrier attackers, Type Zero carrier fighters, "Gekko (moonlight)" Type 99 twin engine light bombers, and also the famous Type 1 "Hayabusa (falcon)" fighters. This engine was mainly produced at the Tokyo Factory and at the Musashino Factory (built in 1938 and later became the Musashi Factory after merging with the Tama Factory), and more than 30,000 units were produced (the highest number in history). The Musashino Factory was an exclusive factory for the Army engines, and this modern factory, with an area of 660,000m2, was the crown jewel of Ichiro Sakuma's outstanding knowledge and labor. Ford's state of the art assembly line operation and the scientific management process of Taylor system were incorporated. In addition, production process, the material flow, and human movement were carefully thought out. A welfare program for employees and first-class facilities were second to none at that time. The Navy was impressed by this, and requested the same kind of exclusive factory be made for them. The Tama Factory was built next to the Musashino Factory in 1941. Later, due to the aggravation of the war situation, Nakajima proposed to unite the both the Army and Navy factories for more efficient operation, but because of hostilities between them, they did not come to an agreement for several years until they were merged into the Musashi Factory. Ichiro Sakuma, who took an active role in Nakajima engine engineering for each plant, also planed and established the Mitaka Research Center, and worked as General Manager in the Construction Department. The intention of the Mitaka Research Center was not only the aircraft research but also to establish a general research center for politics, economics and engineering. Considering this to be a far-reaching program for the future of Japan, a land mass surprising 1.65 million square meters was secured. Coincidentally the ground breaking ceremony was held on the 8th of December 1941, the day Japan entered World War II. But later, due to an aggravation of the war condition, the military was against having such an elaborate research center, and the facility started its operation as a prototype engineering division and prototype manufacturing plant in 1943. (After the war, almost all of its facilities were sold. The main engineering building is now utilized as a schoolhouse of International Christian University.)  As a result of the outbreak of World War II in Europe in 1939, the engines developed in Europe and the US moved toward 1,500~2,000PS class. Because of this, Nakajima formulated a plan to modify "Homare" into an 18-cylinder engine. There were piles of problems in various engineering fields, but with strong support from the Navy, the unique, small, light weight, and high-power "Homare" prototype was completed. Compared with the Mitsubishi engine "Kasei", which had an external diameter of 1,372mm, "Homare" was only 1,180mm in diameter, and brought with it high performance for a plane in which a smaller frontal sectional area was a key factor. This made it possible to develop masterpiece airplanes such as the "Hayate (gale)" and the "Saiun (iridescent clouds)". "Homare" was installed not only in Nakajima planes but also in the bomber "Ginga (galaxy)" and other planes such as the "Shiden (purple lightning)", the "Shiden-kai (Shiden-II)", and the "Ryusei (meteor)", and boasted its exceptionally high power in the world at that time. But because of the war condition, it became difficult to acquire high quality fuel that was required for the engine, maintain the quality level of machining process (due to a lack of skilled workers), and purchase special steel materials. As a result, its performance potential was not fully realized before the end of the war.  - - Take-off power: 2,000PS at 3,000rpm Weight: 830kg External dimension: Overall length; 1,785mm, External diameter; 1,180mm Total production: 8,747 units |

References "30 years of Fuji Heavy Industries"

"Silver Wing Forever" (Ota City)

"Song of Flight" (Nakajima-kai)

Å@Å@ "Japanese Masterpieces of Aircraft" 1959 Zito-sha

"Japanese Aircraft Dictionary" (Model Art Co.)

Collaboration from Communication Division, FHI

Å@

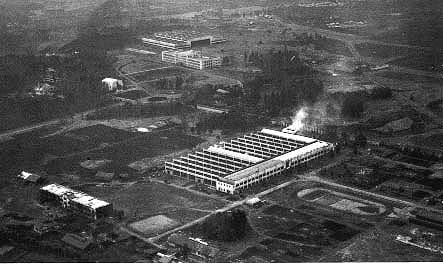

Tokyo

Factory (at Ogikubo, shown in the left picture) in 1924 in pursuit

of domestic production of airplane engines. Even though Nakajima

Aircraft was born in Ota, Gunma, Chikuhei Nakajima decided that

"The factory should be in Tokyo in order to recruit top-class

personnel" and dared to separate body and engine production

by selecting a site in the Tokyo suburbs.

Tokyo

Factory (at Ogikubo, shown in the left picture) in 1924 in pursuit

of domestic production of airplane engines. Even though Nakajima

Aircraft was born in Ota, Gunma, Chikuhei Nakajima decided that

"The factory should be in Tokyo in order to recruit top-class

personnel" and dared to separate body and engine production

by selecting a site in the Tokyo suburbs.

design with the rational

design of the US made Wasp. On this occasion, Nakajima engineered

four engine types, AA, AB, AC, and AD as engineering exercises,

but they were never manufactured. The next engine design, AE,

was highly innovative with a bore of 160mm and a stroke of 170mm.

Prototypes were made and performance tests were done, but this

was not adopted due to its too venturous engineering. In 1929,

the AH with bore/stroke of 146/160mm and a total displacement

of 24.1 litters was worked on. This was to be the final version

of the engine design and failure would not be tolerated, The

engineering was based on a principle of solid, simple and clear

design with the rational

design of the US made Wasp. On this occasion, Nakajima engineered

four engine types, AA, AB, AC, and AD as engineering exercises,

but they were never manufactured. The next engine design, AE,

was highly innovative with a bore of 160mm and a stroke of 170mm.

Prototypes were made and performance tests were done, but this

was not adopted due to its too venturous engineering. In 1929,

the AH with bore/stroke of 146/160mm and a total displacement

of 24.1 litters was worked on. This was to be the final version

of the engine design and failure would not be tolerated, The

engineering was based on a principle of solid, simple and clear

construction. In June 1930, the first prototype

was completed, and passed the durability test for the type approval

in the summer. Then flight tests were started using a Type 90

reconnoiter carrier plane in the autumn. In December 1931, this

engine was approved and adopted by the Navy. It was then installed

in Type 90 reconnoiter carrier planes, Type 90 carrier fighter

planes, and the famous Zero fighters of Mitsubishi. In the beginning,

the Army did not show any interest in this engine being developed

through the Navy instruction as usual, but later adopted it as

Ha-1 Ko engine used in Type 97 fighters, and had little choice

but to recognize its superiority.

construction. In June 1930, the first prototype

was completed, and passed the durability test for the type approval

in the summer. Then flight tests were started using a Type 90

reconnoiter carrier plane in the autumn. In December 1931, this

engine was approved and adopted by the Navy. It was then installed

in Type 90 reconnoiter carrier planes, Type 90 carrier fighter

planes, and the famous Zero fighters of Mitsubishi. In the beginning,

the Army did not show any interest in this engine being developed

through the Navy instruction as usual, but later adopted it as

Ha-1 Ko engine used in Type 97 fighters, and had little choice

but to recognize its superiority.